Introducing the SCX2800A-3 275t Crawler Crane

HSC Cranes, formerly Hitachi Sumitomo Crane, is renowned worldwide for class-leading products of exceptional quality. Drawing from many decades of Japanese crawler crane development, HSC Cranes has recently been introducing to the market its new SCX-3 series.

As the exclusive distributor of HSC Cranes for over 20 years in Australia, Tutt Bryant Equipment has been standing alongside HSC Cranes as a strong and reliable partner with our national network of branches, factory-trained technicians, and extensive service and parts support.

Following the local launches of the SCX1000A-3 (100t) and SCX1500A-3 (150t) crawler cranes, Tutt Bryant Equipment is preparing for the introduction of the next significant SCX-3 model – the SCX2800A-3 (275t) crawler crane.

Building on the highly popular SCX2800-2 crane, which is a mainstay on projects across Australia, the new SCX2800A-3 will likewise come in liftcrane or luffing / tower configurations and it headlines a number of advanced features to further increase performance and efficiency. With nifty backward compatibility that allows interchangeability with components from the older model such as boom insert sections, owners will have much greater flexibility and economical reasons to upgrade to the new SCX2800A-3 while still utilising existing in-service crane components.

Coming off a win at the Good Design Awards 2018 in Japan, the SCX2800A-3 boasts a familiar yet elegant design that will enable efficient transportation, assembly and disassembly, and much improved safety of the crane operator and those working in close proximity.

Along with extra-wide windows, ergonomic designs such as a new large sliding door, a wide platform, and a comfortable and highly functional operator seat aim to reduce operator fatigue and increase functionality. For better visibility when moving loads at height, a tilt mechanism allows the cab to be angled by up to 18o. Optional handrails and walkways from the factory also ensure safety while working at heights.

The operator will benefit from brand new features such as a simple and easy-to-view interface designed to ensure information is provided in the most succinct, intuitive and reliable way possible. Productivity is further enhanced by the fine speed control dials for hoisting, lowering, swinging and boom hoisting operations which are positioned beside the operator for ease of access, while a swing mode selector switch allows the choice between swing-free or swing-brake operation depending on work requirements and personal preferences.

The all-new Load Moment Indicator (LMI) with data-logging capabilities records duty cycle and winch hours, as well as load moment and line pull. These are important features that will allow the crane owner to more accurately calculate the available design life remaining on the machine many years from now. This should, in theory, increase the safe operational age of the machine from current methods employed in complying with the new Australian regulations.

As a standard feature, Remote Sensing is installed in all machines to minimise downtime, ensure accurate maintenance and improve machine marketability.

In addition to a powerful 13.5t rated line pull winch for steady operations, the SCX2800A-3 has an Eco-Winch mode which allows high line speeds under light loads without having to increase the engine speed (low rpm). Bringing lower fuel consumption and reduced noise, this is an eco-friendly feature that will save fuel costs and minimise environmental impacts.

Other clever features are the winch rope Lower Limit Indicators that ensure a minimum of three wraps of hoist rope remain on each drum so as to prevent failure of the rope termination on the drum, along with the wide winch drum design which minimises potential damage to winch ropes.

Productivity gains will also be achieved via a unique combined hydraulic circuit developed by HSC Cranes. By increasing and optimising the pump pressure through the use of a mixed circuit to control the hydraulic oil from two hydraulic pumps, operability is enhanced when travelling, hoisting/lowering, swing and boom hoisting, all of which can be undertaken simultaneously.

While the SCX2800A-3 will be available with Stage IIIA / Tier 3 engines, customers have the option to order the crane with a Cummins QSL9 engine that meets Stage IV / Tier 4 Final emissions regulations. Along with major reduction in exhaust gas emissions, customers will benefit from reduced fuel consumption, saving cost and decreasing CO2 emissions.

What is truly exciting about the SCX2800A-3 are the optional features that provide owners with greater flexibility and efficiency.

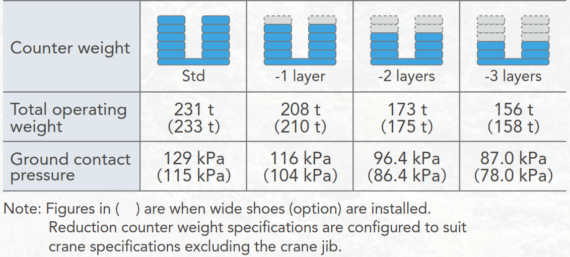

A Reduction Counterweight specification is expected to be widely taken up by customers. By removing counterweights on the upper structure, this feature will allow the SCX2800A-3 to be utilised in four different capacity classes (275t, 260t, 250t and 240t). Coming into its own in situations where lower operating weight / reduced ground bearing pressure are required, the Reduction Counterweight specification will further give owners the flexibility to use the SCX2800A-3 as a lower capacity crane, whereupon the amount of counterweights needed to be transported to a job-site can be reduced.

The SCX2800A-3 also has optional 1260mm wide track shoes, some 140mm wider than the standard shoes. Reducing the ground bearing pressure by 12.5%, this will make the crane more flexible and reduce the requirements for ground improvement tools.

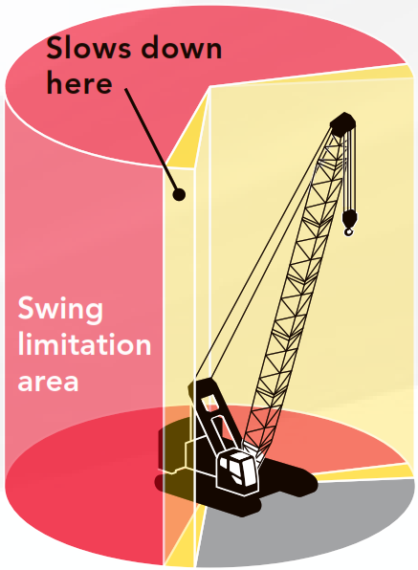

Another option that will greatly improve safety around the crane is the Swing Restriction system. Used to limit the range of slew to pre-set working zones, the system aims to allow smooth operations when working within tight constrained sites. There is an added slow-down function prior to reaching the no-go zone, thereby minimising load swing.

View the SCX2800A-3 275t Crawler Crane here.