Bridging The Gap To A Sustainable Future

Tasmanian construction and civil engineering experts BridgePro Engineering is committed to sustainability. With the help of Tutt Bryant Equipment and its provision HSC SCX2800A-3C5 crawler crane, this commitment is becoming a reality.

Sustainability, a commitment to community, and a desire to build a better future, have been the pillars that BridgePro uses to guide its operation. After all, as Managing Director and Founder, Aaron Brimfield says “we’re part of the community”. Established in December 2010, BridgePro was initially an aptonym – the company specialised in bridges, whether they were road or pedestrian – however, as Aaron explains, a lack of larger projects compelled the company to diversify.

“First and foremost, we build bridges,” he says. “We do foundations for bridges, walls and buildings, but we’ve worked our way into other projects that the state needs, such as marine structures, wharves, jetties, and other civil infrastructure jobs.”

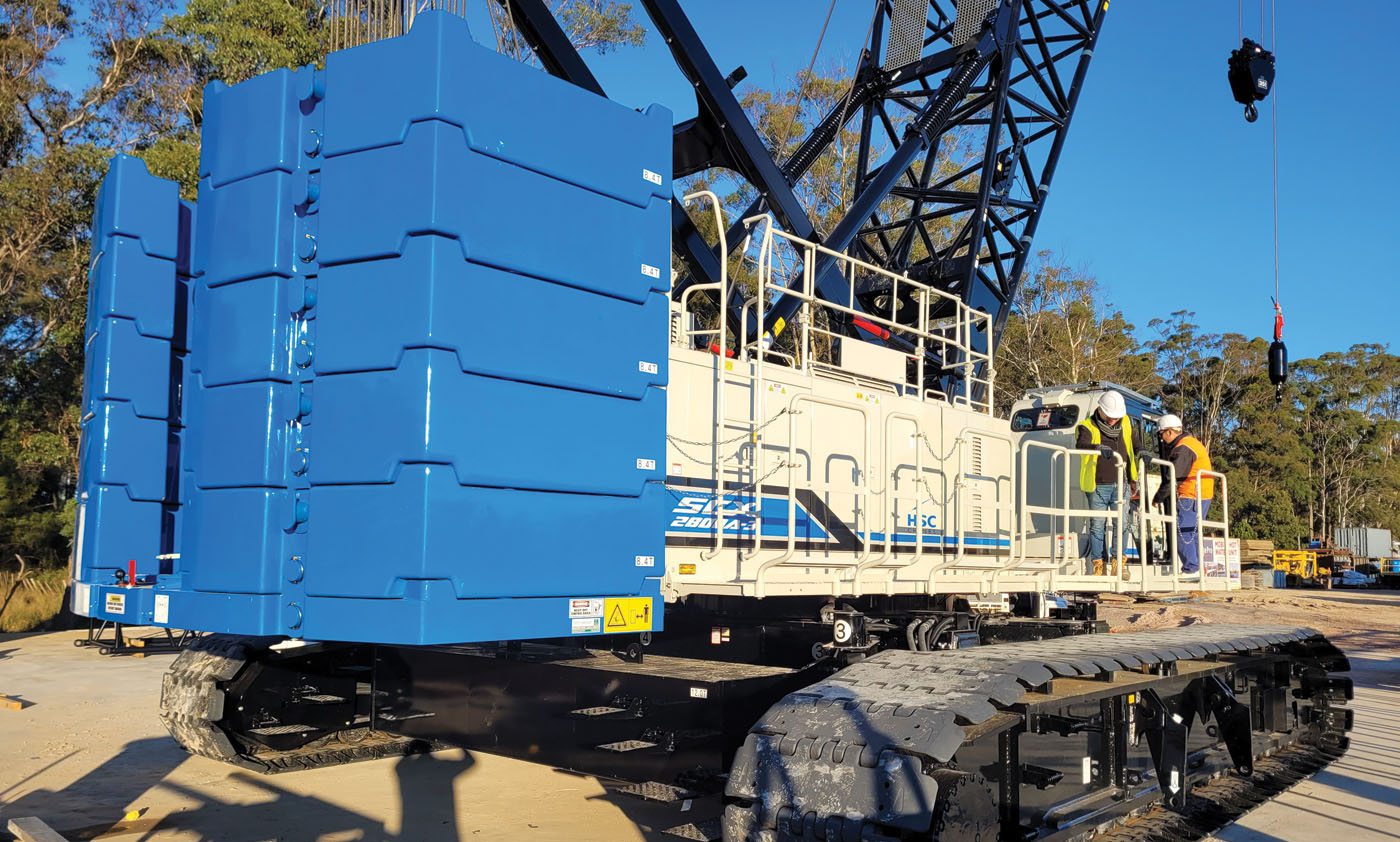

Aiding to the conquest in expanding to other projects are two SCX2800A-3C5 crawler cranes from Japanese company HSC Cranes, purchased through leading construction and heavy equipment distributor Tutt Bryant Equipment.

“We’re looking at projects like the hydrogen plants built by the Marinus link power upgrades in tandem with other things such as wind farms and wind projects”, he says. “It’s what sets BridgePro apart from more traditional construction companies; our engineering focus is that we innovate and try to find better solutions to any given problem.”

“We see lots of opportunity here for upcoming infrastructure projects, and we’re keen to capitalise on them. Hence, the two cranes.”

Receiving the first 275-tonne capacity crane in September last year has allowed BridgePro to expand on its previous business, and the flexibility it has offered the Tasmanian construction experts has been invaluable.

“One of the features of the SCX2800A-3C5 is that it can be operated with reduced counterweights. When we were initially choosing a new crane, we were stuck between the 275-tonner and the 150-tonner,” says Aaron.

“With the reduced counterweight, we equated that to being equivalent to about 180-tonne crane as well as anything in between. The pricing wasn’t too different, and it provides us with the option to work on bigger projects if we take those on.”

Taking the opportunity to expand within the market, Aaron can see the potential for a bright future, keeping an eye on upcoming projects that provide long-term benefit to BridgePro, the community, and the industry; and HSC’s SCX – three series will help them do exactly that.

As mentioned above, sustainability and longevity are at the forefront of BridgePro’s operations, so when Aaron came to Tutt Bryant with a specific request for the lowest emission crane available, Southern Region Sales Manager Philip Chadwick came through with the SCX – 3 Series offering. Powered by a Cummins engine, the SCX2800A-3C5 crawler crane combines a cleaner running engine and advanced control system to provide greater energy efficiency during the crane’s operation.

The engine itself features an advanced, eco-friendly technology – the Urea SCR System – which is a device for the aftertreatment of exhaust gas, that injects urea fluid – AdBlue – into the gas itself to breakdown nitrous oxide gases into its original chemicals of nitrogen and hydrogen; in other words, harmless compounds.

“We took the option and paid the extra to get the lower emission engine,” says Aaron. “It isn’t the standard at the moment here in Australia; the standard is to get the cheaper cranes with the older style engine.”

The newer, more eco-friendly technology that resides within the crane’s engine also means that the machine is compliant with European Union Stage Four and U.S Tier Four exhaust gas emission regulations. In comparison to the previous model, HSC has managed to reduce nitrous oxide and particulate matter by around 90 per cent, meaning that – on top of reduced emissions – the machine requires less fuel and produces less carbon dioxide.

“We’re looking forward to the future, and we see our work revolving around projects to drive towards that net zero,” says Aaron. “It wouldn’t have been right to buy an asset that has a 20 year lifespan and look to the past without looking into the future. And not to mention, we plan to make money out of the crane working on projects that are all about reducing emissions.”

Reduced counterweight capabilities and an eco-friendly design aside, other features of HSC’s 275-tonne crawler include enhanced visibility in the operator’s cab, accessible transportability, a practical counterweight setup process and other main specifications such as 70-metre boom length with an additional jib length of 36 metres.

“We’ve been really happy with the first crane,” says Aaron. “hence the decision on our second one.”

“The project that we’re working on currently is utilising barges for uneven ground, a bit of having to work in a reasonably windy environment,” he continues. “We felt, in this case, spending a bit extra and getting the crane that can be trusted from a source (Tutt Bryant) that we trust was worth it.”

When they first saw the crane coming off the truck, Aaron and the team at BridgePro felt vindicated in their decision to go with the SCX2800A-3C5, noting visual features such as the quality of the welding and the paintwork. “When you buy a Japanese crane like that, you’re not buying it for one job, you’re not going to write it off over the next two years. We bought it as an investment in our long-term future,” says Aaron.

“It was also encouraging to know that HSC hold the belief that their cranes are designed to last 30 or more years,” he continues. “It’s encouraging to know that, that’s the place they’re coming from; they want to provide a service that gives us quality for an extended period of time – there isn’t any short-termism.”

Set to travel to Japan with Tutt Bryant’s Philip Chadwick to visit the HSC factory and inspect the second crane that’s due to land in Tasmania in a matter of weeks, Aaron is nothing but complimentary of the service Tutt Bryant provides to BridgePro and speaks of his excitement in visiting the factory.

“With the decision to buy the lower emission crane, well, that falls into our decision to work on projects that we want to survive for 100 years.”

Dealing with Tutt Bryant

“Phil is a really good salesman. He was able to offer advice based on what we requested and talk us through our options,” he says. “Crane charts, wind charts, load charts – whatever it was that we wanted to know, Phil was really good to us. We can’t fault them – or HSC by default.”

“They’ve constantly been good to deal with and we held no hesitation in dealing with them again, and spending another couple of million dollars wasn’t a problem because we knew the quality of both service and product we were going to receive.”

Also citing Philip’s attentiveness during the process. Aaron is keen to stress that, in line with BridgePro’s ethos and HSC’s mantra on long-lasting quality, Tutt Bryant placed an emphasis on making sure Aaron and the team received the right products for their needs within the parameters of what they wanted.

“The infrastructure that we’re doing is here for the long term; it’s stuff that will last and will make an impact on generations into the future. That idea of constructing for future generations applies across everything we do,” he says.

“The whole basis of what we do and the whole reason why we do what we do is we hold a strong belief that we are making the world a better place for the people in the future.”

As good as their word, BridgePro’s commitment to the local Tasmanian community is evident. Consistently donating to or sponsoring local clubs, organisations and charities throughout the region, the construction experts also host tours of their facilities for year 12 science students at St Brendan Shaw College, whilst also hosting science presentation to local schools.

“We’re a major employer here in Northern Tasmania – probably one of the largest,” he says. “We work on projects all over the place, and a big part of what we do is constructing for future generations.”

“We believe that we need to be a good community partner that helps the community grow, because in turn that helps us improve,” he says. “I believe that by doing good out there in the world and contributing to the community provides untold benefits for us, particularly as most of our workforce comes from the local community.”

SOURCE: Cranes and Lifting Magazine

For more information about the HSC Cranes contact:

Philip Chadwick

National Crane BDM Southern Region – VIC/TAS/SA

0457 510 097

philip.chadwick@tuttbryant.com.au

Peter Lawgall

National Crane BDM – NSW/QLD/NT/ACT

0411 256 388

peter.lawgall@tuttbryant.com.au

Tutt Bryant Equipment

About Us | Explore HSC Cranes

We are equipment sales and after-sales support division of the Tutt Bryant Group.