Metso Mobile: Your Guide to Quarry Productivity

Paul Doran is the business development manager for Metso mobile crushers and screens at Tutt Bryant Equipment. He provides insight into which Metso mobile products are popular, when some of the latest machines and innovations will be available in Australia, and how Metso’s after sales programs and services can benefit quarry producers.

How has Tutt Bryant Equipment (TBE) performed during the global pandemic?

Lead by multiple territory infrastructure project deliveries, increase focus on waste management and funding grants, TBE has performed well. Being an essential service enabled us to be almost business as usual with some process modifications.

Has the pandemic changed the way TBE conducts business with Australian quarries?

An essential service supporting the construction, waste and mining industries we have maintained most business operations but we are ensuring we get our money’s worth from Microsoft Teams!

Which of TBE’s mobile products are most popular in the quarrying industry?

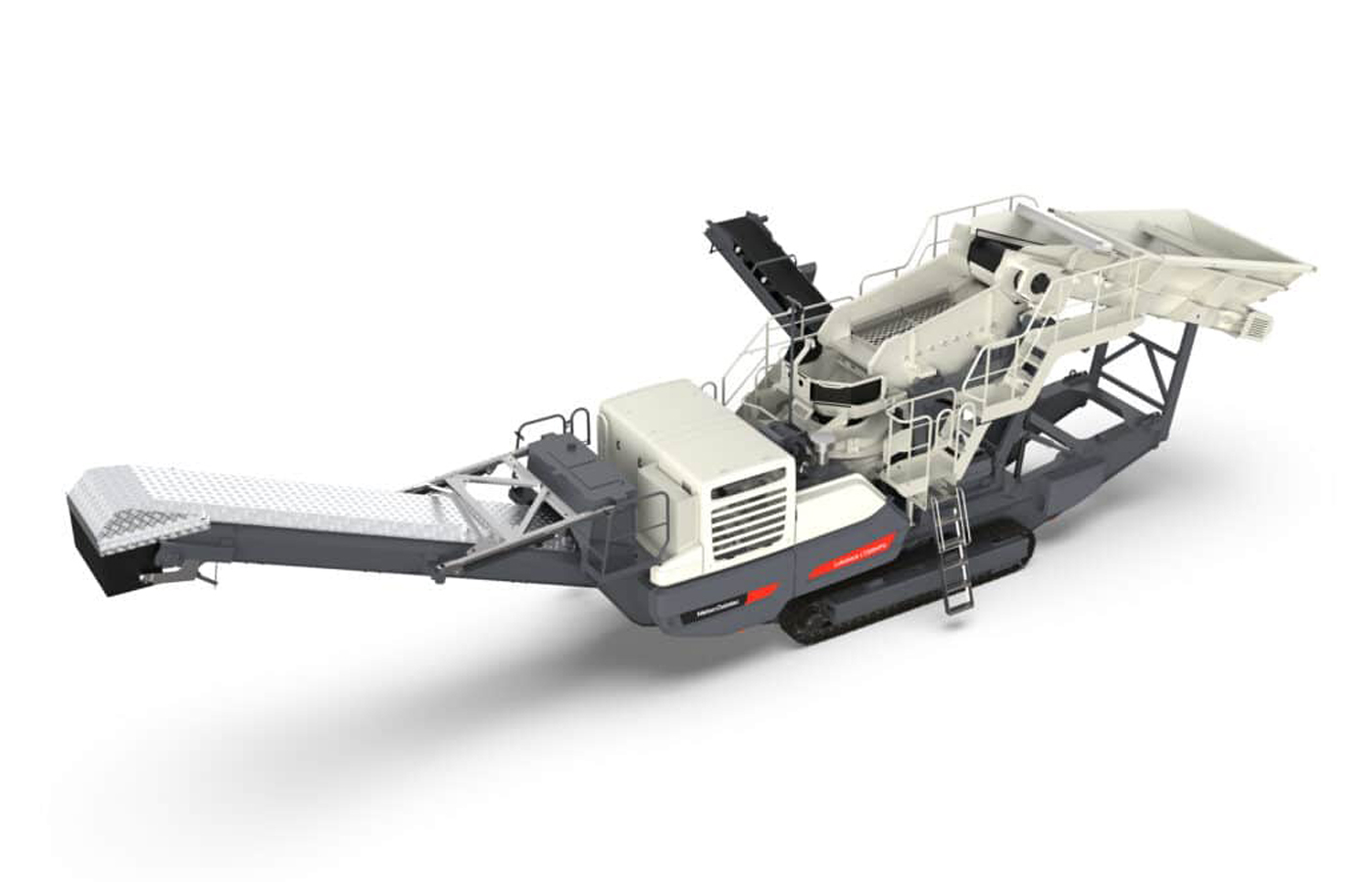

The Metso Lokotrack LT120 is a large, portable jaw crusher with sizeable feed rock capacity. The LT220D is two machines in one, with a cone crusher and a triple-deck screen on the same chassis. It promises half the transport cost and up to 40 per cent less fuel than two comparative units. The LT1213S is a higher volume seller product. Its high reduction is ideal for roadbase construction from quarry rock or recycled concrete.

New machines have joined the Lokotrack range. Are they available in Australia?

The LT200HPX and LT200GP are in production in Finland and we are developing a marketing campaign for their release in Australia. They fill gap between 149kW and 223kW cones and provide a pure secondary-type cone with or without a pre-screen.

Does TBE offer programs and services beyond key mobile plant and equipment?

TBE offers a comprehensive start to finish service on equipment selection, based on application data which provides key inputs into a Bruno simulation. Many customers are surprised that the Bruno software can simulate almost all of the machine adjustments that can be made in the field. It provides them with an accurate guide to productivity, product gradings and the footprint required for their chosen configuration.

Our crushing and screening account managers can show the customer the theoretical energy usage (diesel or electricity for e-units) and regularity of wear component change-outs. We regularly demonstrate to the customer the dollars per tonne cost of wears. When you add the energy usage, finance costs and productivity rates, the customer has most of their production costs estimated.

We can provide scheduled servicing solutions in the form of service contracts to the customer, serial number-specific, well out to several thousands of hours of operation.

When the machines are delivered and commissioned, our specialised service technicians show the operators how to use and maintain them properly. This encompasses fault-finding and maintenance practices to ensure the operators know how to optimise the machine or who to call if they need a hand.

TBE can provide a one-stop shot. We have a wide range of excavators, loaders, skid steers and cranes, and can support our customers with undercarriage, GET and wear products.

What innovations in your products can save time and cost and achieve zero waste?

All of our equipment has fleet management capability in the form of Metso Metrics. It enables owners to monitor the performance and servicing of the machine which hones their management of the asset to reduce costs and energy waste, like unproductive fuel usage.

This is reinforced by the lean toward electric-powered machinery that will become more common place in the next few years.

How advanced in Metso Outotec in developing electric power solutions?

We have e-units in Australia (eg the LT120E, LT130E and the LT330D) and we expect this to expand with the ongoing development of the portable Metso NW Rapid (wheeled) range. The industry is striving to be more efficient and cost-effective which will lead towards either hybrid or fully electrical units in the near future.

What will be the quarry industry’s major challenges in the next three years?

The lack of skilled labour is the most common complaint of our customers. The borders coming down may ease this constraint marginally, but it could take a long time to train people to fill that gap. Several customers have ample work opportunities in front of them and could buy more gear but just don’t have the staff to look after the additional equipment.

Our partners and suppliers are also of the belief that the container deficit could take some time to correct. The cost and timeframe of components and parts shipped by containers is likely to be affected for some time to come.

How can TBE assist with these challenges?

Tutt Bryant is developing an Academy where we will have an active apprenticeship and training program to further support our customers.

We are also extensively reviewing our parts stock nationally to rationalise the location of parts, relative to the mix of units in the market. We have a significantly parts holding in country and extensive parts orders being processed by our OEMs to do all that we can to make sure we have stock when our customers need it.

SOURCE: Quarry Magazine

For more information about Tutt Bryant Equipment’s Metso mobile range and other services contact:

Paul Doran

Business Development Manager (Metso)

0417 970 547

paul.doran@tuttbryant.com.au

Tutt Bryant Equipment:

About Us | Our Metso Outotec Range

We are equipment sales and after-sales support division of the Tutt Bryant Group.