Riverwood Rail Bridge Replacement

Replacing Sydney’s Salt Pan Creek railway underbridge.

Railway underbridge’s play a very important role in transporting everyday commuters to where they need to go. They form an integral part of a railway systems corridor acting as a bridge to pass over whilst also allowing for passenger vehicle traffic to travel under. At Sydney’s Salt Pan Creek waterway, the existing underbridge at Riverwood on the East Hills Railway Line (Sydney NSW) required replacement as it was nearing its end of useful life as determined by the client, Sydney Trains.

The clients project specifications were relatively straight forward – remove the old beams, transport them to a predefined location and then install the new. However, as with most projects, the work involved in achieving the client’s objectives is extremely complex involving significant planning and sound execution. The project breakdown saw Tutt Bryant remove the four 29 tonne spans, each span consisted of two deep riveted beams joined by cross girders. These would then be lifted onto a work train and taken to Chullora rail yard for recycling by Sydney Trains. The 42 new precast deck units were then loaded onto the work train, brought to the site and installed by Tutt Bryant. Having successfully completed a similar project in 2010 for the same client, Tutt Bryant was confident in delivering this project incident-free and with minimal impact on the surrounding community and rail network.

Strategic planning is the key

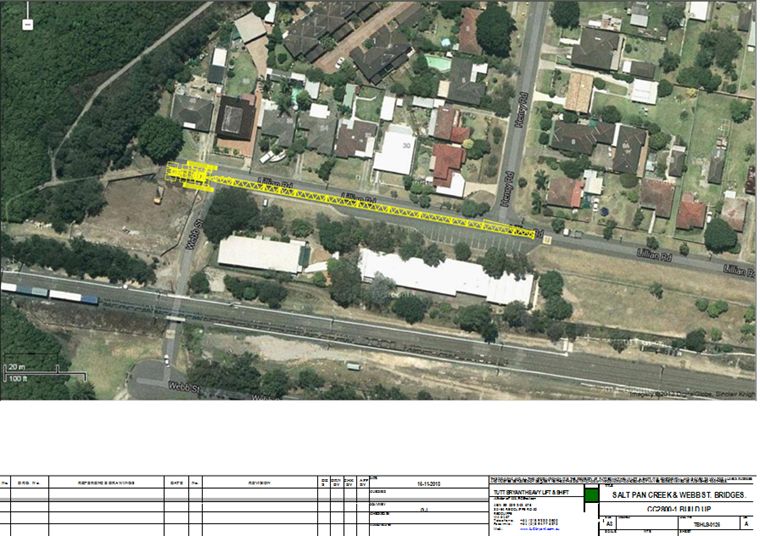

A critical factor to the success of the project was Sydney Trains’ expectation that the project would be completed incident-free. With major works and project setup to be undertaken in a residential side street with the local community and a school located nearby, it was paramount that community safety was considered in all facets of project planning. Tutt Bryant interfaced with the residents and the local school reassuring them their safety was important and that there would be minimal disruption throughout the duration of the project. Project planning began with numerous post-award meetings with both the Sydney Trains and Bankstown Airport project teams in where planning took place to reschedule flight movements for the duration of the project. The enormous benefit obtained from the meetings was a major factor in why the project was delivered so professionally and successfully. Communication was essential in the acceptance by the local community of these complex works without which the project would have stalled in its early stages. The concept of delivering this project using such a large crane, assembled in the tight location of a local council street was extremely daunting. The crawler crane and boom would have to be built on a local residential street leaving little to no room for error and the timing window for the build and lifts were extremely tight as railway lines, air space traffic and roads were closed for the duration of the project. Any setbacks would extend the job time leading to further delays on the transport system.

The main lift crane was transported from Mackay, Queensland to the initial trial assembly area located in Chullora, Sydney. Days before the possession Tutt Bryant re-enacted a number of trial lift scenarios and mimicking our lifting studies to ensure we were ready. With all trial builds, pre-planning and community engagement completed, Tutt Bryant was allocated 48 hours to complete the entire project. To conduct the major lifts, Tutt Bryant utilised a 600T Demag CC2800-1 Pin Jib Crawler Crane configured with 200T of Superlift and 126m of boom. Supporting the 600-tonne crawler was a 220t Liebherr Hydraulic Crane, 80 tonne Liebherr Hydraulic Crane and a 25-tonne Franna Crane. Given an extremely tight project time frame and operational area, Tutt Bryant’s site-specific delivery was programmed on an hourly basis allowing for early intervention to be undertaken to avoid and mitigate any schedule slippage. With the crane build successfully completed, the various removal and installation lifts began and were completed with relative ease due to the exceptional pre-lift planning and schematic development. The removal lifts were aided by the engineering, design and fabrication of a series of beam clamps that safely and efficiently attached to the old girders. They allowed for easy removal and proved to save time in ensuring the lift was undertaken with the load perfectly balanced and more importantly guaranteed to not overstress the old girders at the point of attachment.

The project was completed to the expected time frames and within budget. Although during the 48hr possession Tutt Bryant experienced unexpected difficulties with wind affecting the ability to perform certain lifts, the project team took initiative to facilitate these lifts as quickly as possible managing to recover for lost time. Sydney Trains were extremely pleased with the project’s success. The project was shortlisted in the finals of the CICA lift of the year awards.

Key Equipment – Terex-Demag CC2800-1

The Terex-Demag CC2800-1 boasts a 600-tonne lifting capacity at 10m radius and features excellent lifting capacities throughout the whole range.

The CC2800-1 offers significant efficiencies with its very simple assembly and short rigging time and also offers variable superlift radius allowing for increased range in lift motions.